- E8 Sourcing Insights

- Posts

- 3D Printing: The $94 Billion Revolution Reshaping Manufacturing

3D Printing: The $94 Billion Revolution Reshaping Manufacturing

Discover how additive manufacturing is transforming industries through innovation and efficiency

Market Overview: 3D Printing - The Future of Manufacturing

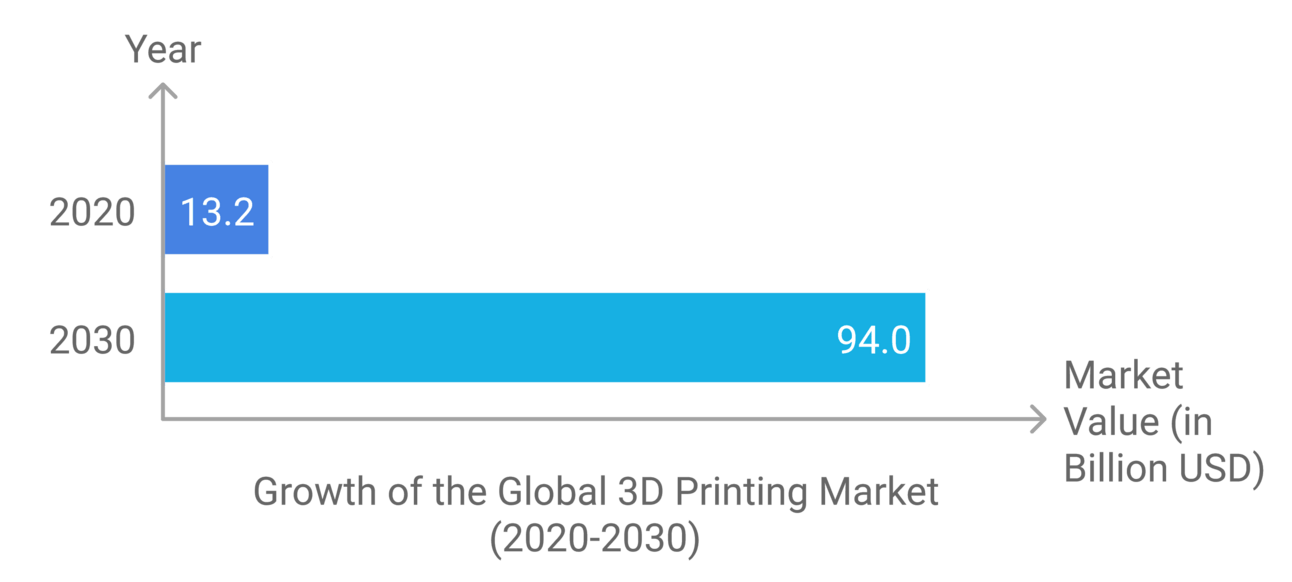

The global 3D printing market, valued at $13.2 billion in 2020, is expected to reach $94.0 billion by 2030, with a CAGR of 22.1% from 2021 to 2030. This explosive growth stems from increased government investment in 3D printing projects, ease of customization capabilities, and significant reductions in manufacturing costs and downtime. From rapid prototyping to end-use parts production, these technologies are reshaping traditional manufacturing processes across multiple industries.

The rise in 3D printing adoption is further accelerated by technological innovations and the willingness of industries to embrace digital manufacturing solutions. Leading sectors such as automotive, healthcare, and aerospace are at the forefront of implementing additive manufacturing, driving both innovation and market expansion. This shift represents more than just a trend—it's a fundamental transformation in how products are designed, prototyped, and manufactured.

Key Drivers: Why 3D Printing?

With technological advancements and changing industry needs, the 3D printing market is experiencing unprecedented growth. The market's expansion is fueled by several interconnected factors:

1. Government Investment: Significant funding in 3D printing projects driving innovation and adoption.

2. Customization Capabilities: Enhanced ability to develop customized products meeting specific needs.

3. Manufacturing Efficiency: Reduction in manufacturing costs and process downtime.

4. Digital Infrastructure: Rising demand for digital solutions, especially in U.S. and Canada.

5. Healthcare Integration: Growing adoption of 3D printing solutions in the healthcare sector globally.

Competitive Landscape: Key Players in 3D Printing

The 3D printing market features established leaders and innovative solutions providers shaping the industry's future:

Established Brands:

3D Systems: Leading pioneer in comprehensive additive manufacturing solutions, offering industrial-scale printing systems and advanced materials for automotive, aerospace, and healthcare sectors.

Stratasys Ltd.: Market leader in industrial 3D printing, specializing in multi-material technology and end-use part production for manufacturing industries.

Autodesk Inc.: Premier provider of advanced design software and manufacturing solutions, enabling seamless integration of 3D printing workflows across industries.

The ExOne Company: Specialized leader in industrial-grade binder jetting technology, delivering innovative metal and ceramic printing solutions.

Protolabs: Digital manufacturing leader offering rapid prototyping services and on-demand production solutions.

Emerging Players:

Optomec, Inc.: Innovative provider of advanced metal additive manufacturing and printed electronics solutions.

Organovo Holdings, Inc.: Pioneering bioprinting technology for medical research and tissue engineering applications.

Voxeljet AG: Specialist in large-format industrial printing systems for rapid prototyping and series production.

Market Segmentation:

By Technology: Stereolithography (22.6% CAGR), Fused Deposition Modeling, Selective Laser Sintering

By Industry: Consumer Electronics and Automotive (40.2% market share), Defense (24.9% CAGR)

By Application: Prototyping, Manufacturing, Healthcare

By Region: North America (49.6% market share), Europe, Asia-Pacific, LAMEA

Emerging Consumer Trends in 3D Printing

As industries embrace additive manufacturing technology, the market is evolving rapidly, driven by changing consumer preferences and technological advancements:

1. Digital Infrastructure Integration: Growing adoption of cloud-connected printing solutions enabling remote monitoring, predictive maintenance, and seamless workflow integration across global manufacturing facilities.

2. Healthcare Applications: Expanding implementation in medical device production, custom prosthetics, and dental solutions, driven by increasing demand for personalized healthcare solutions and cost-effective medical equipment.

3. Defense Sector Innovation: Rapid adoption in military applications, from spare parts manufacturing to advanced weapon systems, reducing supply chain dependencies and enabling on-demand production.

4. Consumer Electronics Focus: Enhanced applications in electronics manufacturing, enabling rapid prototyping, custom component production, and innovative design solutions.

5. Automotive Integration: Expanding use in automotive design and production, revolutionizing traditional manufacturing processes through rapid prototyping and end-use parts production.

Popular Items:

Industrial prototyping and manufacturing equipment for rapid product development.

Medical device production systems for customized healthcare solutions.

Specialized materials for aerospace and automotive applications.

Distribution Channels:

Direct manufacturing services and solution providers.

Industrial equipment suppliers and specialized resellers.

Technical service providers and consulting firms.

Case Study: Carbon 3D - Revolutionizing Manufacturing with Digital Light Synthesis

Carbon 3D has transformed the manufacturing landscape since 2013 through its pioneering Digital Light Synthesis™ (DLS) technology. The company's innovative approach to mass-producing end-use parts has redefined manufacturing possibilities while maintaining consistent quality and speed.

Key Success Factors:

Innovation in Technology: Advanced DLS technology enables superior mechanical properties and production speed.Market Strategy: Focus on end-use parts production rather than just prototyping.

Market Strategy: Focus on end-use parts production rather than just prototyping.

Material Science: Development of proprietary resins that expand manufacturing possibilities.

Business Model: Subscription-based platform ensuring continuous innovation and support.

Strategic Partnerships: Successful collaborations with major brands like Adidas prove scalability.

Lessons Learned:

Focus on End-Use: Successful 3D printing companies target production, not just prototyping.

Material Development: Investment in materials research drives application possibilities.

Partnership Value: Strategic collaborations accelerate market adoption and validation.

Innovation Balance: Combine technological advancement with practical business applications.

Sustainable Growth: Build recurring revenue models that support continuous development.

Carbon 3D's approach combines innovation with practical scalability, showing that breakthrough technology must be paired with sustainable business models and strategic partnerships to achieve mass-market success. Their experience demonstrates how additive manufacturing can move beyond prototyping to transform traditional production methods while maintaining profitability.

Risks, Challenges, & Solutions

1. Professional Workforce Availability:

Challenge: Critical shortage of skilled operators and technicians in additive manufacturing, limiting industry growth potential.

Solution: Implementation of comprehensive training programs, partnerships with educational institutions, and development of specialized certification. programs

2. Data Security:

Challenge: Protecting sensitive design and manufacturing data across digital platforms while maintaining workflow efficiency.

Solution: Implementation of enhanced security protocols, encrypted file sharing systems, and robust cybersecurity measures across the manufacturing network.

3. Standardization Issues:

Challenge: Lack of consistent process control and quality assurance metrics across different platforms and technologies.

Solution: Development of industry-wide standards through collaboration with regulatory bodies, establishment of quality certification programs.

4. Material Limitations:

Challenge: Restricted availability and high costs of specialized printing materials limiting widespread adoption.

Solution: Strategic investment in material research and development, focus on cost-effective alternatives, and development of recycling programs.

5. Equipment Costs:

Challenge: Significant capital investment required for industrial-grade 3D printing equipment and infrastructure

Solution: Development of more affordable solutions, implementation of flexible financing options, and creation of shared facility models for smaller businesses

Future Outlook & Niche Markets

The 3D printing market is positioned for significant growth, driven by technological innovations and expanding applications. This evolution presents exciting opportunities for businesses ready to embrace additive manufacturing:

1. Healthcare Integration: Rapid expansion in medical and dental applications, including customized implants, prosthetics, and anatomical models, revolutionizing patient care through personalized medical solutions.

2. Defense Applications: Accelerating adoption in military and defense sectors, focusing on rapid prototyping of critical components, field-ready parts, and advanced equipment manufacturing.

3. Consumer Electronics: Implementation of advanced manufacturing solutions for electronic components, enabling faster product development cycles and innovative design capabilities.

4. Automotive Innovation: Enhanced prototyping and production capabilities transforming traditional manufacturing, reducing lead times and enabling mass customization.

5. Industrial Manufacturing: Revolutionary streamlining of production processes through on-demand manufacturing, reduced inventory requirements, and optimized supply chain management.

Emerging Opportunities:

Advanced digital manufacturing platforms integrating AI and automation.

Specialized material development for specific industry applications.

Custom production services for niche markets.

Regional Growth:

North America: Leading market share with strong digital infrastructure.

Asia-Pacific: Fastest-growing region with increasing industrial adoption.

3D Printer Supplier 1

Zhejiang Flashforge 3d Technology Co., Ltd.

Founded in 2011, Flashforge is a pioneer in the 3D printing industry, trusted by nearly a million users across over 200 countries. Operating from a 26,000m² facility with over 600 employees, the company invests 15% of annual turnover in R&D, launching 4-5 new models annually. Their commitment to innovation and quality has established them as China's leading R&D-focused 3D equipment manufacturer.

Location: Hangzhou, China.

Products: FDM/DLP/LCD/MJP 3D printers, printing filaments and resins.

Certifications & IP: ISO 9001, ISO 14001, OHSAS 18000, CE, FCC, RoHS, REACH; 134 national patents, 36 software copyrights.

Notable Clients: 3 Idea Technology, Ubercool Gifting Solutions, Altus Engineers, J.K. Marketing.

Unique Strength: Leading R&D capabilities with comprehensive product range from consumer to industrial-grade 3D printing solutions.

Contact: Flashforge Website, Alibaba Link.

Phase 1 Supplier Score: 82/100 – based on an evaluation using Tianyancha Business Intelligence.

3D Printer Supplier 2

Shenzhen Lexcent Technology Co., Ltd.

Founded in 2013, Lexcent has evolved into a comprehensive high-tech enterprise specializing in additive manufacturing technology. With manufacturing facilities across Shenzhen, Xuzhou, and Dubai, the company has established itself as a key player in industrial 3D printing solutions and rapid manufacturing services. Their focus on building and supporting 3D printing service centers has made them a trusted partner for businesses seeking to establish competitive advantages in local markets.

Location: Shenzhen, China.

Products: Industrial 3D printers, rapid prototyping services, manufacturing solutions.

Certifications & IP: ISO 9001:2015, 11 patents, 24 trademarks.

Notable Clients: Big Tech Inc., Huawei, China Eastern Airlines, The Chinese University of Hong Kong.

Unique Strength: Comprehensive service offering combining equipment manufacturing with operational training and rapid manufacturing services.

Contact: Lexcent Website.

Phase 1 Supplier Score: 85/100 – based on an evaluation using Tianyancha Business Intelligence Reports.

3D Printer Supplier 3

Shenzhen Creality 3D Technology Co., Ltd.

Founded in 2014, Creality has established itself as a world-leading consumer 3D printer manufacturer. Operating from a 150,000m² facility, the company has built a comprehensive ecosystem around its core 3D printing business, including scanners, laser engravers, and the Creality Cloud platform. Their "One Core with Two Wings" business strategy has driven global expansion, with products reaching over 100 countries and consistently topping global 3D printer sales charts.

Location: Shenzhen, China.

Products: Ender series, HALOT series, Sermoon series, 3D printing filaments, scanners, and accessories.

Certifications & IP: RoHS, CE, FCC; Red Dot Design Award, Display Industry Award (SID), 560+ patents., 5 trademarks

Notable Clients: Krause Trade, Markus Trade, Yousea, Matterhackers

Unique Strength: Comprehensive ecosystem combining hardware, software, and cloud solutions with strong focus on consumer accessibility.

Contact: Creality Website, Alibaba Link.

Phase 1 Supplier Score: 80/100 – Learn more about how we use Tianyancha Business Intelligence Reports to evaluate suppliers in our Academy.

China Exhibitions: Sourcing Next-Gen 3D Printing Solutions

Here are a few upcoming events that should be on your radar:

10th 3D Printing Intelligent Equipment Exhibition (DMP): Nov 26-29, 2024, Shenzhen – This premier event in Asia's 3D printing industry showcases the latest innovations in additive manufacturing technology. With its focus on industrial applications and smart manufacturing solutions, DMP offers valuable insights into China's rapidly evolving 3D printing sector. The exhibition is essential for professionals seeking cutting-edge technology and manufacturing partnerships.

International 3D Printing Expo (Asiamold Select): Feb 25-27, 2025, Guangzhou – A key platform for the additive manufacturing industry in southern China, featuring comprehensive displays of industrial 3D printing equipment and advanced manufacturing solutions. This expo is particularly valuable for businesses looking to connect with suppliers in the automotive, medical, and electronics sectors.

TCT Asia 2025: March 17-19, 2025, Shanghai NECC – As China's largest 3D printing and additive manufacturing exhibition, TCT Asia brings together industry leaders and innovators. The event showcases next-generation technologies and offers unparalleled networking opportunities with key decision-makers in the Asian market.

These exhibitions offer valuable opportunities for global manufacturers to connect with China's thriving 3D printing ecosystem and establish relationships with leading suppliers. Attendees can gain firsthand exposure to cutting-edge additive manufacturing technologies and explore strategic partnerships that will shape the future of industrial production and rapid prototyping.

Founder's Corner: When Manufacturing Gets Personal

While putting together this newsletter about 3D printing, I found myself getting really excited about where things are heading. What caught my attention wasn't just the technology – it was how 3D printing is making everything more personal.

Think about it: printing your own custom insoles, dentures that fit perfectly, or a mouth guard for sports. This isn't some far-off future thing – it's happening right now. As someone who works in sourcing every day, I can see how this is changing the whole game of how we make things.

We're moving away from the old "one-size-fits-all" approach. Soon, many of us will have 3D printers at home, creating solutions for our specific needs. For those of us working with Chinese manufacturers, this is something we need to watch closely. Many factories are already adding 3D printing to their traditional production lines.

I think we're heading toward a future where custom-made becomes the normal thing, not the special thing. For businesses, this means we need to think differently about how we make and source products.

– Jiling

Conclusion:

The 3D printing market represents a transformative force in manufacturing, driven by technological advancement and increasing adoption across key industries. As businesses prioritize efficiency and customization, the demand for additive manufacturing solutions continues to rise.

For manufacturers and businesses, success in this market will depend on understanding evolving industry needs, embracing advanced technologies, and addressing key challenges like workforce development and material limitations. By focusing on specific applications and maintaining adaptability, businesses can position themselves to capture a share of this rapidly expanding market.

As we move forward, the 3D printing industry is poised for continued growth and innovation. Those who can adapt to changing trends, address challenges creatively, and consistently deliver value will find themselves at the forefront of this manufacturing revolution.

Looking ahead: In next week's edition, we'll dive into the rapidly expanding e-bike market, projected to reach a staggering $118.6 billion by 2030. We'll explore how advancements in battery technology, increased urbanization, and growing environmental awareness are driving this market forward. Stay tuned as we uncover the latest trends, key players, and strategies to help you tap into this dynamic sector and revolutionize urban transportation with eco-friendly solutions.